|

DKG2C is an Austin Mini Cooper S, from early 1965. You will see from the photos that it does not have any bumpers. Also, some of the trim inside, plus the use of perspex windows all round (except the windscreen) is unique to a particular specification that BMC tested in 1967. DKG is built to a 1967 group 6 (prototype), lightweight specification. BMC had the intention to make this as light as possible, plus using various engine modifications (such as a weber 45) to gain as big an advantage over their competitors as they could. For those who know their works cars, DKG is very similar to LRX827E, which one the 1967 Alpine Rally. In fact, this car was rebuilt alongside LRX a number of years ago when it was undergoing some refurbishment itself.

Over the years it has competed a number of rallies, most recently with Peter Barker and Willy Cave, taking part in multiple Monte Carlo Historique rallies. DKG2C finished as high as 21st in 2011 out of approximately 350 cars and 2nd in its class!

The car was bought by the current owners in 2013, and it was apparent that at some stage (sooner rather than later!) that the car would need some attention. The paintwork was starting to fall off, there were a few knocks on it as well and just generally needing some attention.

After the car taking part (and being put through it's paces) in a couple of touring assemblies in Ireland and France it was deemed in 2015 that it was time to take a look at what as truly going on underneath the paintwork and address it. With a completion date set for November 1st (as it was due to take part in a rally in France on that day) it arrived at the Mini Works in February.

The goal was to restore the car, but at the same time to retain it's aged/original look and not to make it a showroom looking rally car. As much of the car was to be re-used...all accessories, both inside and out and the engine (which was only refurbished a year prior).

Stripping of the car commenced straight away, with many photographic records being made to ensure that all period works modifications were kept, and to try and reduce time in all the re-assembly.

Because a works wiring loom is probably one of the most important (and difficult) items on a works rally car, the intention was to work around this. Therefore, the restoration was carried out with the loom in place. Detailed mapping of all routing and connections was completed before actual bodywork was carried out.

|

Above: DKG2C and our 1964 Works replica HMX135B. Both of these cars have been on a number of touring assemblies and events, with HMX heading down to Monte Carlo every other year since 2004!

Below left: DKG before the strip down commenced with its livery from the 2011 Monte Carlo Historique!

|

|

|

|

|

|

|

|

|

|

As the state of the bodywork was unknown to start off with, the engine was kept in, with the hope that it would just be some outer wings, and perhaps some front panel work.

|

|

Removal of the outer wings then led to noticing the inner wings were also in dire need of replacing. Therefore it was deemed necessary to remove the engine as well.

|

|

Below, the welding and panel build up begins! Inner wings now in situ. Cross member had to be addressed as well. Notice that the wiring loom is still in place. Some careful welding was needed here as we had to work within about 1 inch of it!

|

|

|

|

As we started to investigate more, we noticed that the A-panels, door skins and also the rear quarter panels needed replacing!

|

|

By the time we got to the rear of the car, it was obvious the the boot floor was rotten, and in turn it was decided that with at least half the floor also needing attention, we might also replace all of it.

|

|

DKG now having it's coat of tartan red. Snowberry white was chosen for the roof. Although DKG is a 65 Cooper S, it was built to 1967 Group 6 lightweight specification...which complicated matters as to what shade of white should be used. BMC changed the shade they used during 1967, so a call had to be made as to when DKG would have been converted.

|

|

|

|

|

|

|

In the picture below you will see that the front bumper panel has been trimmed back, so that there aren't any mounting holes. This is due to the group 6, lightweight spec that it is built to.

|

|

Once DKG had been painted, it was returned to the workshop for the start of the build up. Subframes, suspension and respective components were placed on first.

|

|

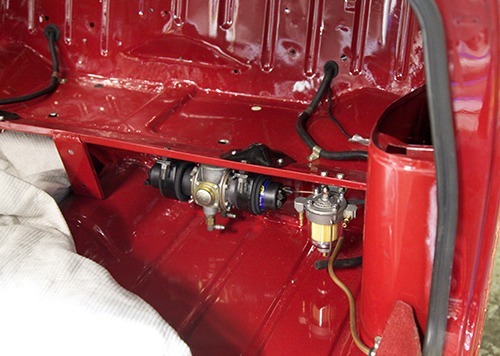

All braking and fuel pipework was routed inside the car as to prevent damage on events. You will notice that the fuel lines are travelling down oneside of the car, seperate from where the wiring loom is...for obvious reasons!

|

|

Wiring for the dash slowly started to appear again. The wiring loom has been routed back through the bulkhead, back towards the rear of the car, into the dash panel area and also up inside the A pillar, along the roof line and back down the C pillar into the boot to feed all the components required.

|

|

|

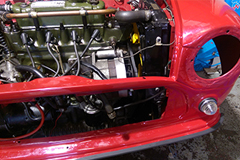

Engine now back in. All electric components such as relays, fuses etc were mounted first. All wiring was routed right through to the front to the headlamps as well.

Due to lack of bumpers, DKG has to have rubber edging instead.

|

|

|

|

|

|

|

|

Twin fuel pump (built in redundancy in case of failure) is placed under the rear seat. You can see the fuel lines leading from the front to the pump, and then fuel hoses from the pump through the rear bulk head into the boot...which then leads to the twin tanks.

You can also see that just abouve the fuel pump on the rear bench, a spare wheel clamp base. DKG has 2 spare wheels on the rear bench (instead of seats) utilising works designed quick release clamps.

|

Rear parcel shelf liner is in place. These have 2 wheel braces in situ. Also the twin tanks are now strapped in with the hoses attached, plus some of the wiring laid out for further fixing.

|

|

|

|

More wiring......this time from the fuse boxes out to each component. Alot of line testing to ensure connectivity at this point. Rollcage had to be squeezed back in as well...not a nice job, when you have a freshly painted car! Note the trim is in place at the back..no trim up front however, due to the lightweight spec.

|

|

Dashes are in place and so are various other items such as carpet, handbrake, gear lever etc.

|

|  |

|

Doors and bonnet are back from the paintshop. These are the next items on. Navigator door needs to be wired up due to the switch panel that will be there.

|

|

Finally all the windows are put in, wipers, grill, spotlights etc. Ready for MOT and out on the road again!

|

|

Below: DKG at the old Reims race circuit in France. This was taken on an a touring assembly down to Monte Carlo, taking in alot of the old Monte Carlo Rally routes. You will notice that the livery on the car is slightly different to how it was prior to the rebuild. The 108 is based on the rally number the car had when it won the Coupe des Alpes rally back in 2010. The small yellow sticker with a '6' is to identify that it is a Group 6 car...these were used originally back in the 60's.

|