A word from Kevin Murray,

563 MWL is one of the pre-production prototype cars built by BMC in September 1961. It was used for the Autocar road test article in early 1962 and was allocated to the press department. It was purchased in 1964 by Tom Morris, the Service Director at BMC. He proceeded to modify the car by fitting a Shorrock supercharger to the 850cc engine. In 1967 the car needed a bit of rejuvenation so a major overhaul was carried out by the Service Department.

The bodywork was tidied up and re-painted Autumn Gold with a Champagne roof, the interior was re-trimmed in Amber, a new goldseal 998cc Cooper engine and gearbox was fitted together with the supercharger. Many other components were added including a right hand tank, fog, spot and reversing lights, fresh air heater and a new instrument panel. The car was developed by BMC to produce more power than a Mini Cooper S 1275.

The car later passed into the hands of a second hand book dealer who had the car “restored” in 1989 after several years the car found its way to me in very poor condition although largely complete. I coaxed the engine back into life and it appeared in good health.

|

|

|

|

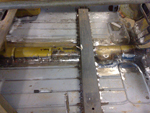

The gearbox has now been stripped, inspected and rebuilt requiring very little new parts. The block and crankshaft were both in good condition but are being bored and ground to make them perfect again. The Cooper cylinder head is having larger exhaust valves and hardened seats fitted to allow the use of unleaded fuel without the need for additives.

The body has been completely stripped to asses and ultimately repair all corrosion. There is quite a bit and a lot of work ahead repairing it. The car will be re-painted in the colour scheme that Tom Morris had the car painted in 1967 and not the later restored colours.

The interior trim is in very good condition, requiring little more than a good clean and most of the chrome work although not perfect, will be re-used. The suspension has been fully rebuilt, requiring only the front hubs re-assembled to complete the running gear.

|

|

|

|

|

|

|

|

|

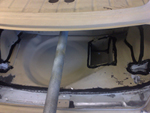

Significant progress made this week. Both floorpans/sills have been repaired or replaced as necessary. This was more complicated than it sounds. The new pans were carefully let in to the existing floors to maintain as much of the original floor as possible and a few repair sections were needed to the offside tunnel and both toeboard ends. The rear subframe mounting panel ends have been repaired but they still need to be attached to the inner sill. We hope to do this by removing a section at the bottom of the rear map pocket to allow us to weld through to the mounting panel. The cross-member has been replaced as the original was too badly corroded and damaged by previous repairs.

Today the rear arches and boot floor have been removed and the edges dressed ready for new panels to be fitted. Most of the original detailing has been transferred over to the new floor but a couple more are still required, tomorrow we hope to complete this and do a fit up of the new parts. The offside arch is clamped in place and appears to fit well. The nearside is a bit more complicated as it appears the vertical shock absorber mounting part is for an offside arch although numbered for nearside, a new one will have to be sourced. Next week the boot floor should be completed and the shell dropped off at the sand blasters to treat the remaining corrosion. On its return we can then complete the closing panels, do the map pocket repairs and attack the front end!

|

|

|

With Simon now back from his second trip to America some progress has been made once more. The shell has come back from having selected areas blasted and it has been given a coat of heavy primer to protect the exposed metal. A repair has been carried out to one of the corners of the bonnet, which required letting in and then fabricating the edges and folds from a piece of sheet metal, which was not simple by any means. The next big task is to tackle the front end...

|

|

|

Work has now started on repairing the front inner wings. It has been cut out to save as much of the original section as possible and then a heritage replacement panel matched and welded in place. It's a time consuming task and there is a lot more work to do. The door pockets are now also in place but require more work which will have to come after some other repairs are carried out to the rear section.

|

|

|

|

|

|

|

|

The door steps and A panels were now been fitted after measuring and adjusting with the doors in place to make sure of a good fit. The engine is due to arrive either this weekend or next week and the shell should be ready to begin prep for painting around this time if all goes well fitting the wings and front panel. The front panel is having to be repaired in an unusual way to keep as much of the original panel as possible. There are a lot of bespoke panels and quite a bit of lead which means measuring, cutting, fabricating and welding takes up a lot of time and brain power, more so than on a Mini. Once work to the shell is complete it will take around 3-4 weeks to get it in paint, the clock is ticking and it is going to be tight... Very!

|

|

|

|

|

|

|

|

|

|

|

|

The front panel was rotten around the valance and the top corners. The solution was to cut the valance above the bumper strip and continue up around the edges. It was then a case of cutting a new front panel out and welding it in in reverse and then weld back in all the original brackets, easier said than done.

|

|

|

The wings and front panel are now finally in place. The wings/A panels being de-seamed were tricky due to the problem of the metal becoming thin after cutting the seam out and getting the front panel and bonnet alligned perfectly due to the amount of alterations previously carried out. It was a slow and arduous process taking 2 days to achieve but the results were worth it. Short cuts could have been taken, however the rigidity and strength would have been compromised. The final spots of welding, shaping and patching will go ahead tomorrow and then the process of prepping for paint will(hopefully) begin.

|

|

|

Well a day longer than expected and the shell has been finished and moved along the road to the painters. This is where the shell will take shape and where the deadline HAS to be met. At the same time every component that has to go on the car will have to be checked and repaired if necessary. It's like a Scottish version of American Hot Rod, only with an Elf, and it's raining, there's a lot of other cars to do and it's not on TV.

|

|

|

3 1/2 weeks later and the shell is now finished and in paint. It is staggering to see how good it looks compared to where it all began and the gold finish looks far better than I thought it would. True to its origins, the engine bay, boot and arches are all painted in its original colour, just as it was after the first colour change. Building it all back together started today and already the assembled subframes and engine/gearbox are installed, with a little help from The Mini Works new apprentice Nick McLaren. It will be ready!

|

|

|

|

It lives! The engine has been started, interior is in and the dash works after some niggles were ironed out with a little help fron Andy Grant. All that is left is to fit doors, boot and bonnet, then check everything again before its MOT.